Introduction

Pasteurization is a crucial process in food and beverage production, ensuring the safety and preservation of products like milk, juices, and other perishable goods. A pasteurization machine plays an essential role in this process, applying heat to kill harmful bacteria while maintaining the quality of the product. But what exactly is a pasteurization machine, and why is it so vital in industries like dairy, juice production, and even pharmaceuticals?

In this article, we’ll explore the importance ofpasteurization machines, their working principles, types, benefits, and how choosing the right machine, such as those from Nantong Bolang Machinery Technology Co., Ltd., can make a significant difference in product quality and safety.

What is Pasteurization?

Pasteurization is the process of heating a liquid or food product to a specific temperature for a set period to kill harmful microorganisms, such as bacteria, yeasts, and molds. This process prevents spoilage and extends shelf life while preserving the nutritional value and taste of the product.

The pasteurization machine is designed to perform this process with precision, ensuring consistency in every batch. It’s used extensively in dairy, beverage, and food processing industries.

How Does a Pasteurization Machine Work?

At its core, a pasteurization machine uses heat exchange technology to treat liquid foods. The machine raises the temperature of the product to a certain level, maintains it for a required time, and then rapidly cools it to prevent any further bacterial growth.

The working principle involves:

Heating: The liquid is passed through a heat exchanger where it is heated to the required pasteurization temperature.

Holding: The product is held at this temperature for a specific period to ensure the destruction of pathogens.

Cooling: After the required time, the product is cooled rapidly to prevent overcooking and preserve its taste and texture.

Different machines vary in terms of the heat source (steam, hot water, or electric), and some systems offer more energy-efficient solutions to reduce operational costs.

Types of Pasteurization Machines

There are several types of pasteurization machines, and selecting the right one depends on the nature of the product and the production volume. The primary types include:

1. Batch Pasteurization Machines

Batch pasteurization is ideal for small-scale production. In this system, a batch of the product is heated to the required temperature in a large tank or vat. It’s then held at the desired temperature for a set period before being cooled down. While slower than continuous systems, batch pasteurization offers flexibility for different product types.

2. Continuous Pasteurization Machines

As the name suggests, continuous pasteurization is designed for high-volume production. The liquid continuously flows through a heat exchanger, ensuring that each portion of the product is pasteurized as it moves through the system. This type of pasteurization is faster and more efficient than batch pasteurization, making it suitable for large-scale operations.

3. High-Temperature Short Time (HTST) Pasteurization Machines

HTST pasteurization is a highly efficient method used primarily in the dairy industry. The product is heated to a high temperature (around 72°C or 161°F) for a brief period (usually 15-20 seconds). This method preserves the taste and nutritional value while effectively killing harmful bacteria.

4. Ultra-High Temperature (UHT) Pasteurization Machines

UHT pasteurization involves heating the product to temperatures above 135°C (275°F) for just a few seconds. This process allows products to be stored for longer periods without refrigeration, making it a popular choice for milk and juice production. UHT pasteurization machines are designed for high-volume, long-shelf-life products.

Why is Pasteurization Important?

Pasteurization is critical for several reasons:

Food Safety: It eliminates harmful bacteria, viruses, and parasites that can cause foodborne illnesses.

Shelf Life Extension: It increases the shelf life of products without the need for preservatives.

Preservation of Nutrients: While pasteurization kills harmful organisms, it also helps preserve vitamins and other beneficial nutrients in the product.

Flavor Retention: Proper pasteurization maintains the natural flavor and aroma of the product.

For companies in the dairy, juice, and beverage industries, investing in a high-quality pasteurization machine is essential to ensure the safety and quality of the products while meeting industry standards.

Advantages of Using a Pasteurization Machine from Nantong Bolang Machinery Technology Co., Ltd.

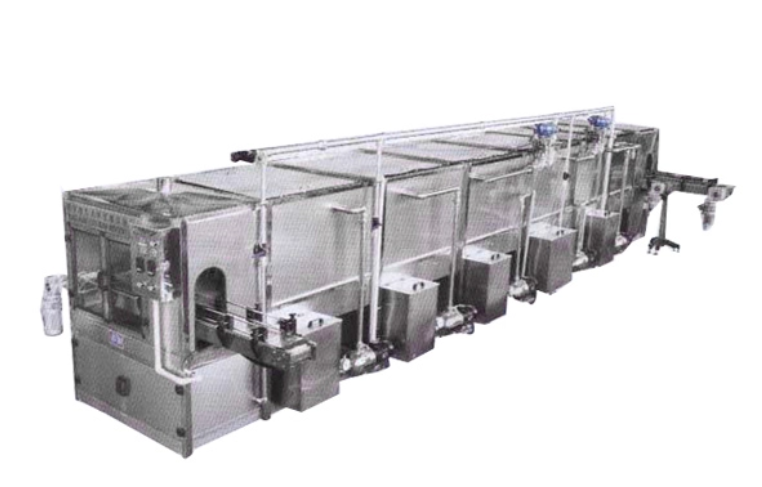

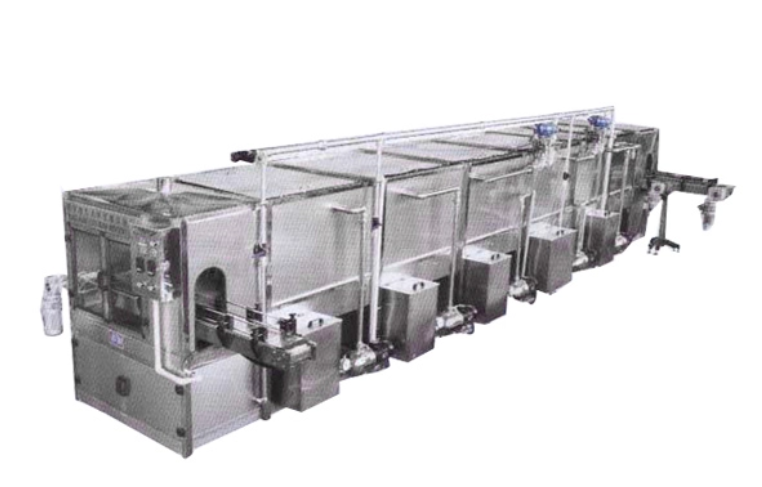

Choosing the right pasteurization machine can make a big difference in production efficiency and product quality. Nantong Bolang Machinery Technology Co., Ltd. offers cutting-edge pasteurization solutions designed to meet the diverse needs of different industries. Their machines come with a variety of features, such as:

Energy Efficiency: The machines are designed to minimize energy consumption while maximizing output.

High Precision: With advanced temperature control systems, the pasteurization process is highly accurate, ensuring product consistency.

Durability: Built with high-quality materials, these machines are designed to last, offering long-term reliability and minimal maintenance.

Customizable Solutions: Whether you need a batch pasteurizer for small-scale production or a continuous system for large volumes, Nantong Bolang offers tailored solutions to meet specific production needs.

Investing in pasteurization equipment from Nantong Bolang Machinery Technology Co., Ltd. ensures that you are using the best technology available to safeguard your products and optimize production efficiency.

Latest Trends in Pasteurization Technology

As industries evolve, so do pasteurization methods. Some of the latest trends in pasteurization technology include:

Green Pasteurization: Many companies are opting for more environmentally friendly pasteurization solutions, including solar energy-powered systems and low-energy technologies.

Microbial Resistance: Research into how pasteurization affects various microbial strains is advancing, enabling machines to target specific pathogens more effectively.

Automation: New pasteurization machines come with automated controls, reducing human error and increasing efficiency.

Smart Machines: Some pasteurization machines now include smart technology, offering real-time data analytics to monitor the process and optimize performance.

FAQs

Q: How long does pasteurization take?

A: The time required for pasteurization depends on the temperature used and the type of pasteurization. For instance, HTST takes about 15-20 seconds, while batch pasteurization might take longer.

Q: Is pasteurized milk safe to drink?

A: Yes, pasteurized milk is safe to drink as the process eliminates harmful bacteria that could cause illness.

Q: Can pasteurization affect the taste of the product?

A: Pasteurization can have a minimal impact on taste, but modern machines are designed to preserve the product's natural flavor and aroma.

Q: What industries use pasteurization machines?

A: Pasteurization machines are commonly used in the dairy, juice, beverage, and even pharmaceutical industries to ensure product safety and quality.